-40%

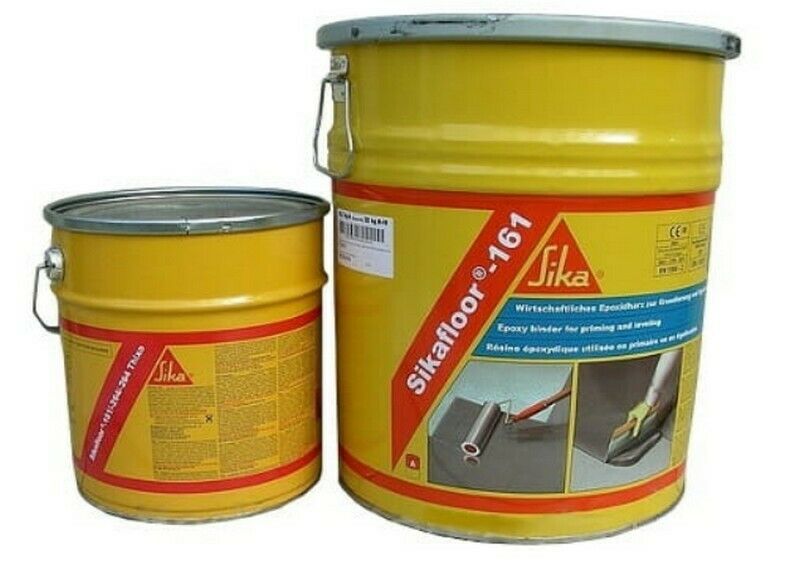

Sikafloor 151 (Sikafloor 161) 2K Primer Epoxy Resin 1014.4oz Bodenbeschicht

$ 289.75

- Description

- Size Guide

Description

Sikafloor 151 (Sikafloor 161) 2K Primer Epoxy Resin 1014.4oz BodenbeschichtThe description of this item has been automatically translated. If you have any questions, please feel free to contact us.

Sikafloor® 151 (Sokafloor 161) 2-component

Epoxy resin primer 30L A + B

Sikafloor 161 epoxy resin primer as primer or leveling on concrete and cement screed, for normally absorbent surfaces. Primer for Sikafloor coating systems. Sikafloor 161 epoxy resin primer is very suitable as a barrier primer on heated screeds.

Good penetration ability

Mechanically high strength

Easy dosage

For increased residual moisture

Short waiting times

Application areas:

Use as a primer or leveling on concrete and cement screed, for normally absorbent surfaces. Primer for Sikafloor coating systems. Blocking primer on heated screeds.

Consumption:

Primer:

Consumption 0.35 - 0.55 kg / m2 per work step, depending on the absorbency of the substrate. A continuously dense, closed resin layer must be created.

With 2 work steps or exceeding the max. Waiting time must be loosely sprinkled with quartz sand 0.4 - 0.7 mm; Sand consumption max. 1.0 kg / m2.

Excess sand is brushed off cleanly before the next step. sucked off.

For an optimal pore closure, the primer should always be primed in 2 work steps, whereby the first work step must be carried out by intensive brushing.

In the area of application of a surface protection system according to Rili-SIB (2001) or according to din V 18026, the AbP or the information on the execution is binding. Work with falling temperatures.

Note:

When overworking with self-leveling coatings, primers must not be scattered in excess! Basically, primers must not be sprinkled when overworking with conductive film.

Leveling filler: (on primer Sikafloor-161) Composition at + 15 ° C to + 20 ° C: At + 10 ° C surface resp.

Air temperature the proportion of sand approx. 30% or at + 30 ° C the proportion of sand approx. Increase 30%.

Processing information:

The subsurface must be sufficiently stable (compressive strength min. 25 N / mm2). The surface must be level, with a fine grip, firm, dry, free of grease and oil and free of loose and silting parts.

The tear-off strength must not be less than 1.5 N / mm2. The compatibility with old coatings must be checked.

Dense surfaces made of hard materials as well as surfaces produced with post-treatment agents, liquefiers or other chemical additives can impair the adhesion of coating materials if the substrate is insufficiently prepared. Test areas are to be created here.

Layers that are not sufficiently stable and soiling must be removed mechanically, e.g. by blasting or milling. Defects, holes or breakouts must be leveled out with Sika products. Stir component A by machine before mixing.

Carefully combine components A + B in the prescribed mixing ratio before processing. To prevent the liquid from splashing or spilling over, mix the components for a short time at a low speed using an infinitely adjustable electric mixer.

Then increase the stirring speed to a maximum of 300 rpm for intensive mixing. After approx. 2 minutes add the intended proportions of quartz sand.

The mixing time is at least 3 minutes and is only finished when a homogeneous mixture is obtained. Transfer the mixed material into a clean container (repot) and mix again briefly as described above.

Delivery form:

Tinplate bucket of 30 kg (A + B): Comp. A: 23.7 kg comp. B: 6.3 kg

Colours:

brownish-transparent

These goods are production goods and cannot be exchanged!

Approvals / standards:

Basic examination according to the DAfStb guideline 10/2001

Test certificate for OS systems according to din EN 1504-2 and din V 18026 for the protection and repair of concrete structures

As a used and mechanically strong coating in OS 8, OS 11a and OS 11b.

Important information

If you need a larger quantity and we don't have that many pieces on auction, drop us a line and our team will evaluate the goods and the shipping.

We invite you to our other auctions. We have a wide range of building materials and interior finishing tools !!!

* ONLY ORIGINAL FROM THE MANUFACTURER *

MasterBau has been active on the European market for 10 years as a distributor of various building materials from Caparol, Graco, Fakro, Tytan, Knauf, Mapei and many others.

Our motto is customer satisfaction through the highest quality of the delivered products.

Some of the products we have purchased can be returned within 14 days in their original sealed packaging or without giving a reason. be returned in their original condition.

Returns are made at the buyer's expense.

If you have any complaints, please contact the following address:

MasterBau Patrycja Chlebowicz

Karl-Liebknecht Str. 6

GEB. "B" OFFICE No. 2U

17321 Locknitz

rating

We welcome any positive review.

If you are unsatisfied or have any problems with shipping, please don't hesitate to contact us before evaluating.

Sikafloor® 151 (Sokafloor 161) 2-component Epoxy resin primer 30L A + B Good penetration ability Mechanically high strength Easy dosage For increased residual moisture Short waiting times Application areas: Consumption: Primer: Note: Processing information: Delivery form: Tinplate bucket of 30 kg (A + B): Comp. A: 23.7 kg comp. B: 6.3 kg Colours: brownish-transparent These goods are production goods and cannot be exchanged! Approvals / standards: Basic examination according to the DAfStb guideline 10/2001 Important information * ONLY ORIGINAL FROM THE MANUFACTURER * Returns are made at the buyer's expense. If you have any complaints, please contact the following address: MasterBau Patrycja Chlebowicz Karl-Liebknecht Str. 6 GEB. "B" OFFICE No. 2U 17321 Locknitz rating We welcome any

Marke

Sika

EAN

7612894675894

Ausgewählte Suchfilter

Bodenbeschichtung

Maßeinheit

kg

Modifizierter Artikel

Nein

Lufttemperatur

+10 °C, max. +30 °C